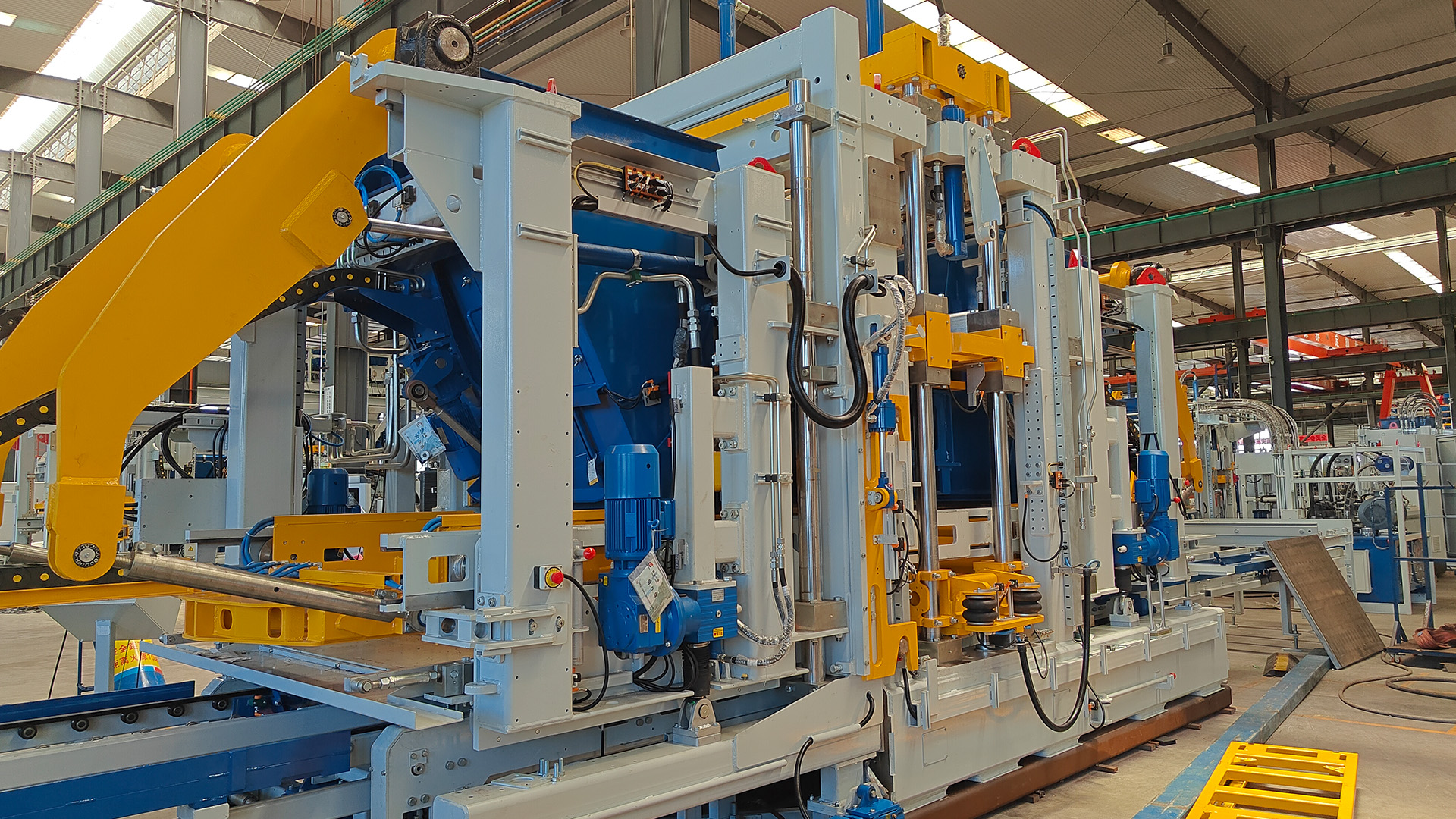

Efficiency Defines Excellence · Intelligence Shapes the Future — QGM ZN1500-2C Intelligent Block Making Machine

As the construction industry moves toward industrialization and green manufacturing, QGM Group continues to lead the way in smart equipment innovation. The ZN1500-2C Intelligent Block Making Machine, as QGM’s flagship model, combines superior performance, stability, and digital intelligence to deliver exceptional value for high-end concrete product manufacturers worldwide.

1. Powerful Performance, Higher Efficiency

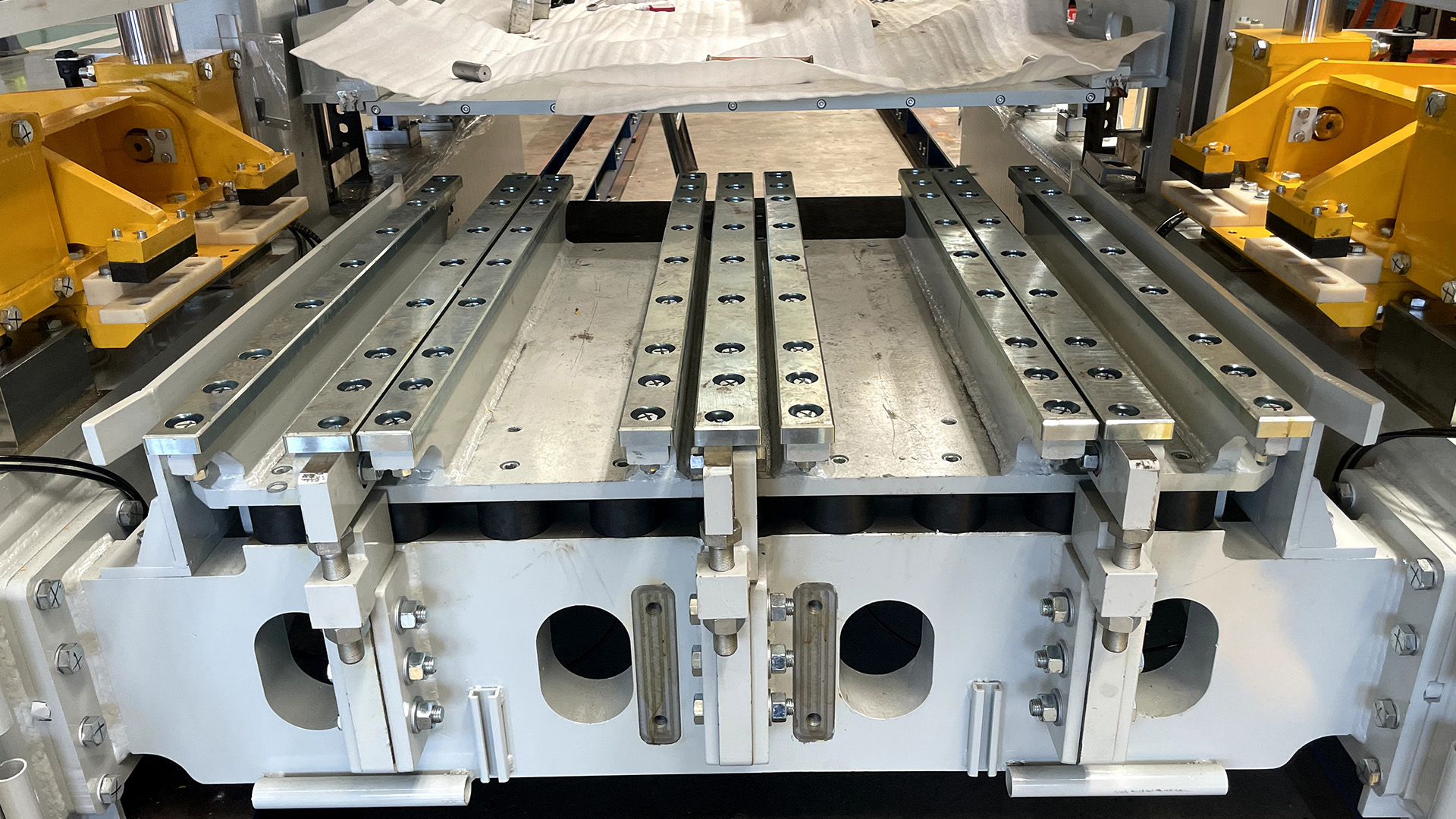

The ZN1500-2C integrates servo vibration and hydraulic forming technology, delivering a maximum forming pressure of 150 tons. Its high-frequency servo vibration system ensures precise energy control, resulting in blocks with higher density, superior dimensional accuracy, and smoother surfaces.

The vibration table, designed using finite element analysis, distributes vibration energy evenly, guaranteeing long-term stability even under intensive production.

With a single-shift output of up to 28,000 standard blocks, it significantly enhances production efficiency and profitability.

2. Intelligent Control, Data-Driven Management

Equipped with a Siemens PLC central control system, the ZN1500-2C offers a clear and user-friendly interface for fully automated control of feeding, vibration, demolding, conveying, and stacking.

Through QGM’s self-developed Intelligent Cloud Service Platform, users can remotely monitor equipment performance, receive real-time fault alerts, analyze energy consumption, and automatically generate production reports — enabling fully digital and transparent factory management.

3. Modular Design, Flexible Production

The ZN1500-2C adopts a modular mold-changing system, allowing operators to switch molds quickly and easily produce various products such as standard bricks, hollow blocks, pavers, curbstones, slope protection blocks, and imitation stone products.

From municipal roads and landscape paving to building construction, this machine provides a one-stop solution for diverse production demands.

4. Green and Energy-Efficient Manufacturing

As a non-fired block machine, the ZN1500-2C uses a cold-press forming process that eliminates the need for energy-intensive kiln firing, minimizing emissions and environmental impact.

Its servo-driven hydraulic system reduces energy consumption by up to 20%, while the optimized feeding mechanism ensures efficient material utilization — achieving the perfect balance between performance and sustainability.

5. German Precision, Global Service

Jointly developed by QGM and Zenith (Germany), the ZN1500-2C represents the fusion of German engineering and QGM’s global service excellence.

The model has been successfully deployed in Southeast Asia, the Middle East, Africa, and Europe, earning wide recognition for its reliability and high-quality output.

QGM provides full lifecycle support — from equipment installation and commissioning to operator training and maintenance — through its international service centers and spare parts warehouses, ensuring stable and efficient operation for every customer.

The ZN1500-2C Intelligent Block Making Machine is more than a piece of equipment — it is a symbol of QGM’s commitment to intelligent manufacturing and green production.

Moving forward, QGM will continue to advance its smart technologies and global service capabilities, empowering the building materials industry to achieve greater efficiency, intelligence, and sustainability.