Stable Performance · Flexible Efficiency | QGM QT6 Block Making Machine for Reliable Mid-Scale Production

As the construction materials industry shifts its focus from sheer scale to efficiency and quality, mid-sized block manufacturers face increasing demands for equipment that is stable, cost-effective, and versatile. The QGM QT6 Block Making Machine is specifically designed to meet these needs, offering a proven structure, consistent product quality, and flexible production capabilities—making it an ideal solution for steady and sustainable factory growth.

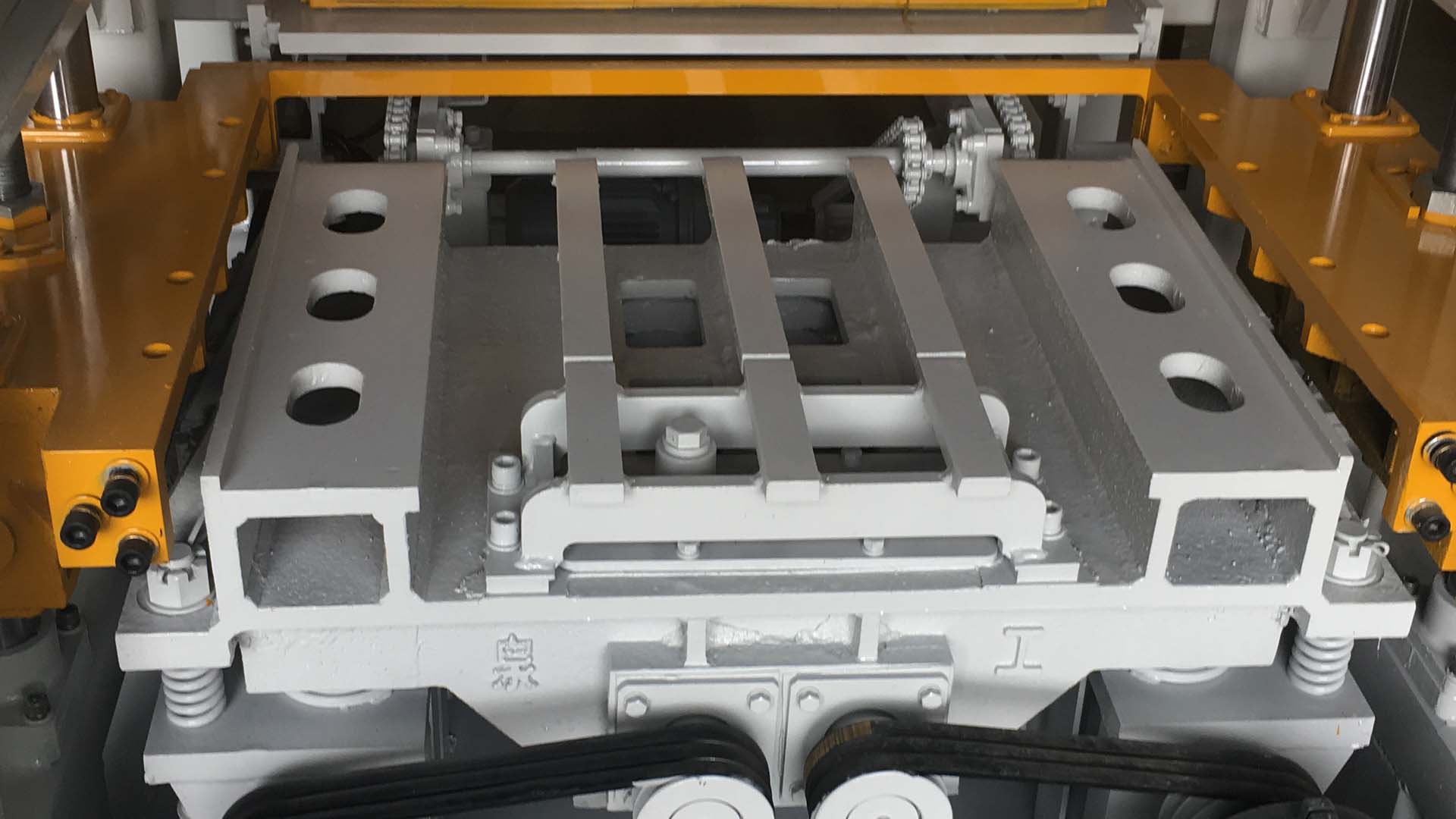

01 Proven Structural Design for Long-Term Stability

The QT6 features a high-strength steel frame with a compact and well-balanced layout, delivering excellent vibration resistance and long service life. Even during continuous production, the machine maintains stable operation and consistent forming accuracy, reducing maintenance requirements and minimizing downtime.

All key components are manufactured and assembled to strict standards, ensuring reliable performance under medium-intensity, long-term operating conditions—perfect for mid-scale block plants or phased capacity expansion projects.

02 Efficient Vibration System Balancing Quality and Productivity

Equipped with a mature and reliable vibration forming system, the QT6 enables fast and uniform compaction of concrete materials inside the mold. Key benefits include:

Stable block density

Uniform compressive strength

Good surface finish

Balanced production cycle with controlled output

Whether producing standard concrete blocks or paving and landscaping bricks with higher appearance requirements, the QT6 consistently delivers reliable quality.

03 Multiple Product Types from a Single Machine

With quick mold replacement, the QT6 can produce a wide range of concrete products, including:

Hollow blocks

Solid bricks

Multi-hole blocks

Paving stones

Slope-protection blocks

Grass-planting and selected special-shaped bricks

This versatility allows manufacturers to serve municipal projects, building construction, and landscaping applications with a single machine, expanding market opportunities.

04 User-Friendly Operation Reducing Labor Dependence

The QT6 is equipped with a centralized control system featuring clear logic and an intuitive interface, allowing operators to quickly master machine operation. Key forming steps—feeding, vibration, and demolding—are automatically controlled, reducing human error and improving production consistency.

For factories with limited skilled labor, the QT6 helps lower workforce dependency while improving overall operational efficiency.

05 Strong Raw Material Adaptability for Cost Control

The QT6 supports various raw material combinations, including river sand, manufactured sand, stone powder, and fly ash. With proper mix designs, recycled aggregates from construction waste can also be used.

This adaptability enables customers to utilize locally available, low-cost materials, effectively reducing production costs while maintaining stable product quality.

06 Reasonable Investment with Stable Returns

Compared with large-scale production lines, the QT6 requires lower initial investment and simpler auxiliary equipment, making it suitable for:

New mid-scale block factory projects

Production line upgrades

Regional building material manufacturers seeking steady expansion

Its mature technology and reliable performance provide customers with predictable output and long-term value.

QT6 — A Practical and Reliable Block Making Solution

With its stable structure, flexible production capability, and strong cost-performance ratio, the QGM QT6 Block Making Machine has been widely adopted across global markets. QGM remains committed to delivering durable, efficient, and sustainable block-making solutions that support customers’ long-term growth.