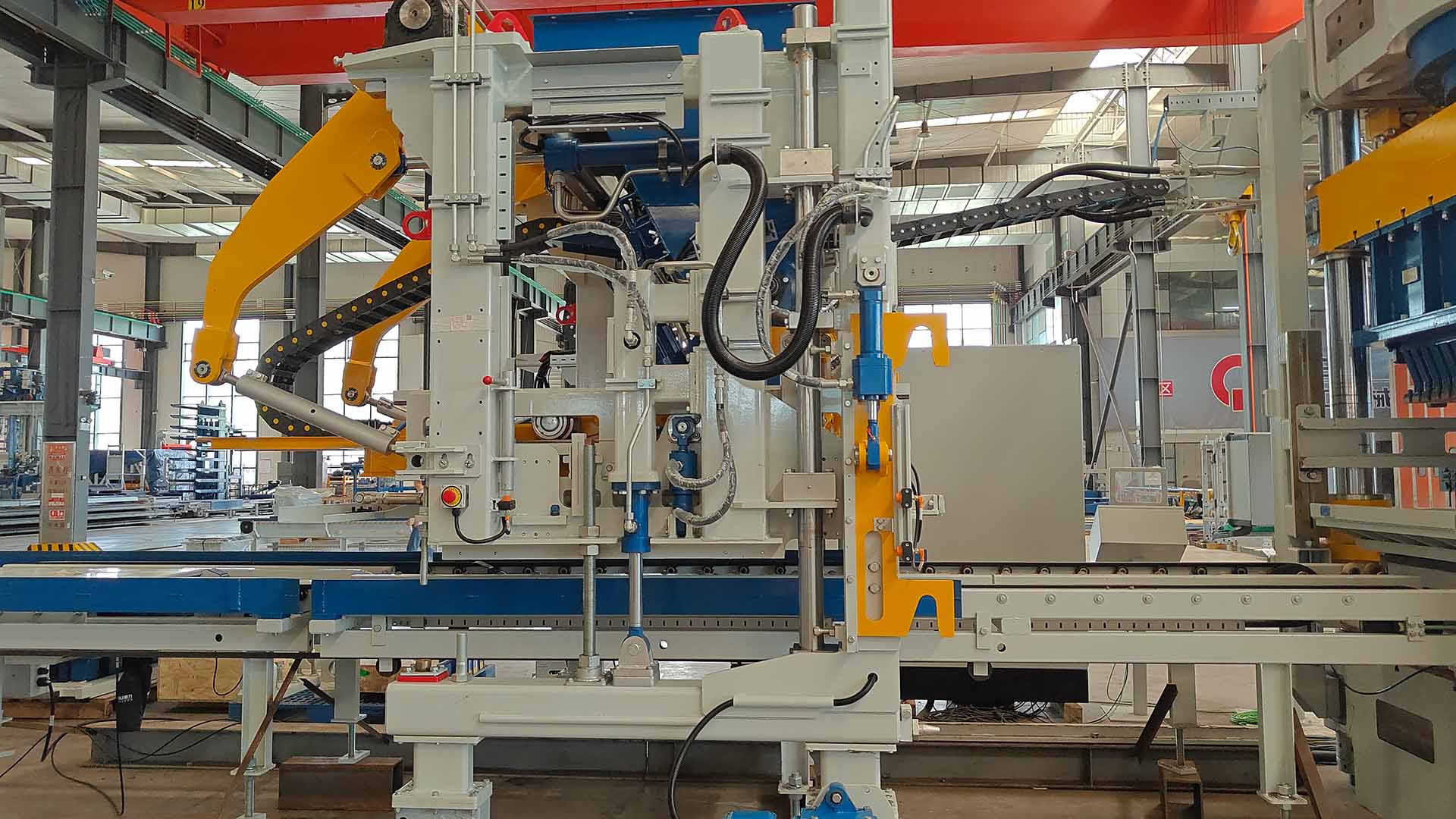

Technology Spotlight|QGM ZN900Y Static Press Machine – High Pressure Forming, Smarter Manufacturing

With the rapid growth of the green building materials industry, brick-making equipment is now expected not only to deliver high efficiency but also to ensure energy savings and superior product quality. QGM’s ZN900Y static press machine, with its combination of large-tonnage static pressing and intelligent control systems, has emerged as an ideal solution for municipal engineering, landscaping, and high-end building materials markets.

1. High-Tonnage Static Pressing – Stronger & Denser Products

The ZN900Y applies a maximum static pressure of up to 1,500 tons. During the forming process, raw materials are compressed evenly and tightly bonded, resulting in products with outstanding density, compressive strength, and wear resistance. Bricks such as curbstones, grass-planting blocks, and permeable pavers can withstand heavy traffic and harsh weather conditions, making them particularly suitable for urban roads and landscaping projects.

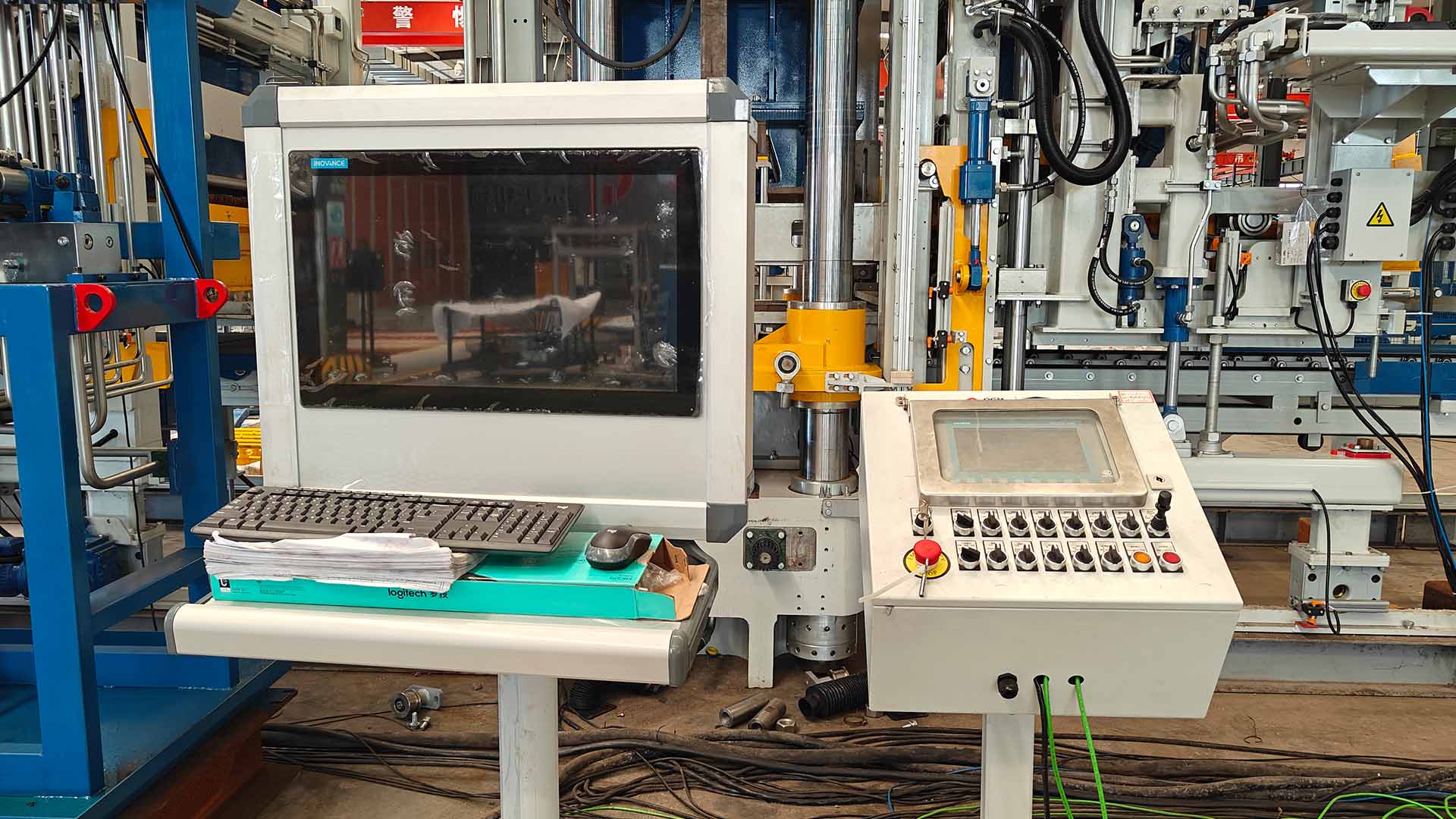

2. Intelligent Control – Easy & Reliable Operation

Equipped with a Siemens PLC system and a user-friendly Chinese/English touchscreen interface, the ZN900Y enables one-touch start/stop, parameter monitoring, and real-time fault alarms. Operators can quickly learn to use the system with minimal training. Moreover, production data can be uploaded to a cloud platform, allowing enterprises to achieve remote management, diagnostics, and maintenance.

3. Flexible Molds – Multiple Product Options

Thanks to its modular mold design, the ZN900Y allows fast and efficient mold changes. Customers can flexibly produce:

Large-sized curbstones

Eco-friendly permeable bricks

High-strength solid blocks

Customized landscaping bricks and special shapes

This versatility ensures that the machine meets the needs of municipal engineering, landscaping, and real estate projects, helping customers expand their product portfolio and market reach.

4. Green & Energy-Efficient – Non-fired Production

As a non-fired brick machine, the ZN900Y adopts cold press forming, eliminating the need for energy-intensive kilns. Its production process generates zero emissions while consuming less energy compared to traditional methods. The machine can also efficiently utilize fly ash, tailings, construction debris, and other solid waste materials, turning waste into valuable resources and aligning with China’s “dual carbon” strategy and sustainable development goals.

5. Proven Applications – Widely Recognized by the Market

The ZN900Y has been successfully applied in South China, North China, as well as in overseas markets. It has been used to produce high-strength curbstones and permeable pavers for urban road renovation, sponge city construction, and landscape projects. Customers consistently report that compared to conventional equipment, the ZN900Y not only lowers raw material and energy consumption but also significantly improves product added value.

6. Comprehensive Service – Worry-Free Support

Every ZN900Y is backed by QGM’s end-to-end service package, which includes on-site installation, commissioning, operator training, and regular inspection. In addition, QGM offers remote technical support platforms, ensuring quick troubleshooting and stable production line operation for customers worldwide.

Conclusion

As a flagship model designed for high-end markets, the QGM ZN900Y Static Press Machine combines large-tonnage pressing, intelligent operation, and versatile mold design to fully meet the industry’s requirements for efficiency, product quality, and sustainability. Looking ahead, QGM will continue to advance static press forming technology, empowering customers to achieve greener and higher-quality development in the building materials sector.