Global Power, Intelligent Manufacturing|QGM ZN2000-2C Fully Automatic Concrete Block Machine

At the forefront of modern concrete block production, the QGM ZN2000-2C intelligent brick machine stands as a symbol of high performance and advanced manufacturing. Jointly developed by QGM (Quangong Machinery) and ZENITH Germany, this flagship model integrates cutting-edge vibration, hydraulic, and control technologies to deliver exceptional production efficiency and product consistency — redefining high-end concrete block manufacturing standards.

1. High-Pressure Forming, Superior Density

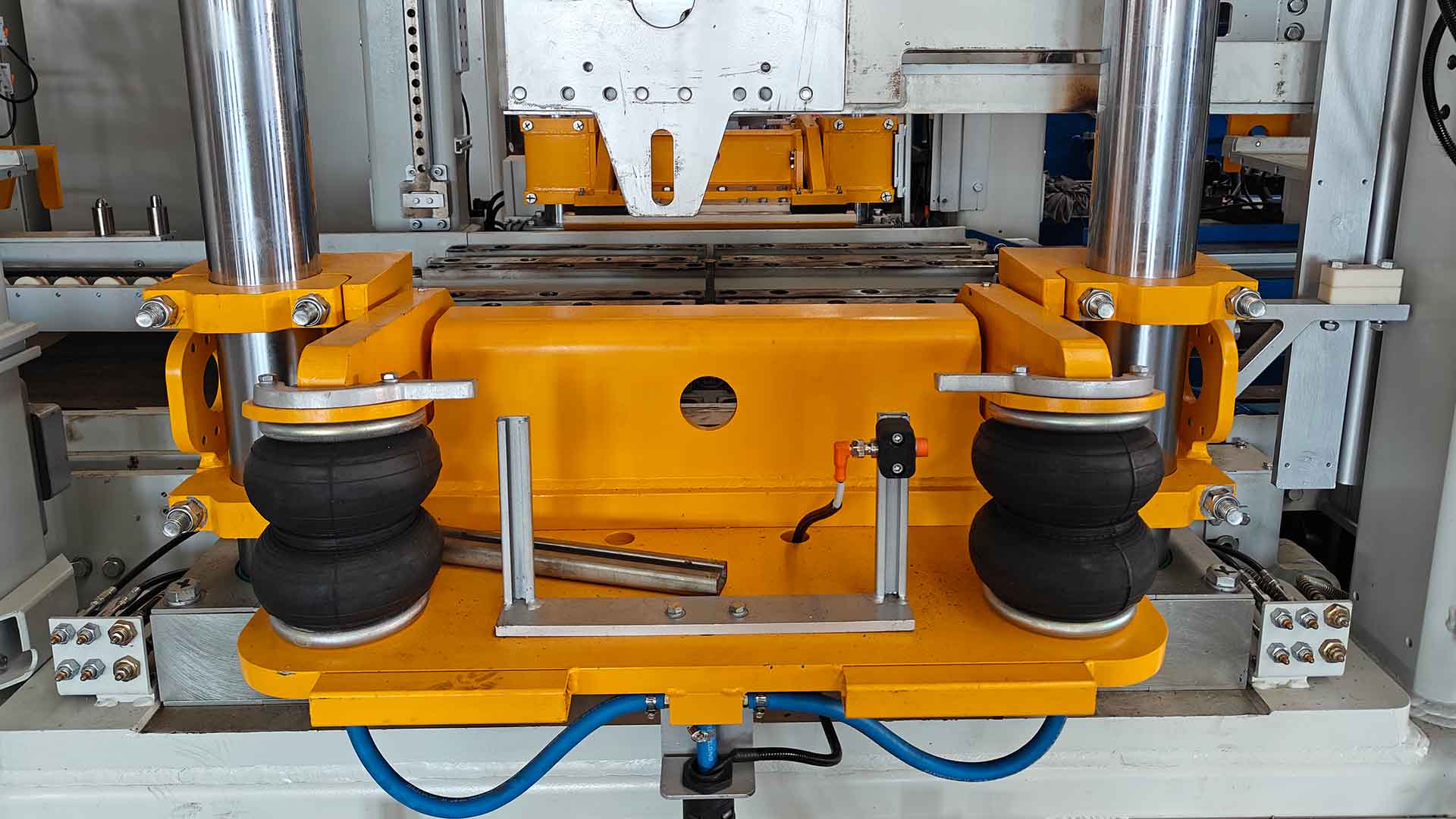

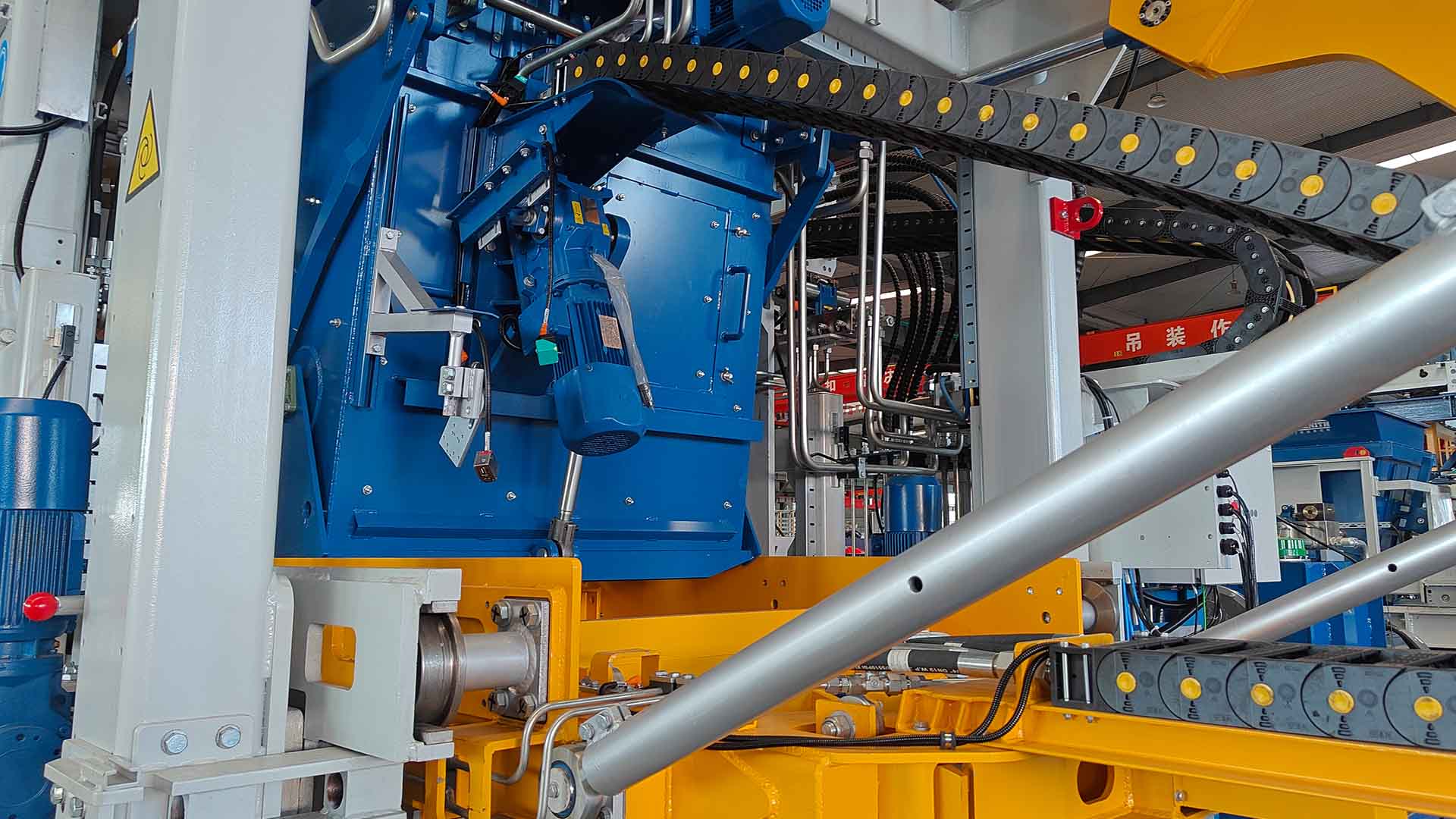

The ZN2000-2C is equipped with a high-performance hydraulic system, providing a maximum forming pressure of up to 200 tons, ensuring that each block achieves outstanding strength and uniform density.

The servo vibration system allows precise control of frequency and amplitude, effectively eliminating air voids in the concrete mix. Whether producing pavers, hollow blocks, curbstones, or decorative bricks, the machine guarantees excellent surface smoothness and structural integrity.

2. Intelligent System for Smart Production

Driven by a Siemens PLC control system, the ZN2000-2C supports full automation of feeding, vibration, molding, demolding, and stacking. Real-time data monitoring and cloud connectivity enable remote diagnosis, performance optimization, and production management, empowering operators with digital tools for smarter decision-making and predictive maintenance.

The integrated data collection platform continuously records operational parameters such as vibration curve, cycle time, and oil temperature, forming a digital foundation for intelligent factory management.

3. Robust Structure and Precision Engineering

The ZN2000-2C adopts a high-rigidity frame made from precision-welded steel, ensuring long-term structural stability even under continuous high-pressure cycles. Its modular design simplifies mold replacement and system maintenance, reducing downtime and increasing equipment availability.

All hydraulic components are sourced from globally renowned suppliers, ensuring stable operation, minimal oil leakage, and excellent durability in demanding production environments.

4. Green, Efficient, and Sustainable

As a non-fired (eco-friendly) brick machine, the ZN2000-2C utilizes cold-press forming instead of traditional kiln sintering, completely eliminating fuel combustion and CO₂ emissions. Energy consumption is reduced by over 20% compared with conventional production methods, fully aligning with global low-carbon development goals.

The machine can flexibly process various raw materials — such as crushed stone, sand, fly ash, tailings, and construction waste — enabling localized resource utilization and circular production.

5. Global Applications and Customer Trust

The ZN2000-2C has been widely deployed across Asia, the Middle East, and Africa. Its stable performance, precise control, and adaptability make it ideal for large-scale infrastructure projects, municipal engineering, and landscape paving applications.

Users consistently praise its efficiency, reliability, and ease of maintenance — recognizing it as a cornerstone for intelligent, green, and sustainable manufacturing.

QGM ZN2000-2C Intelligent Non-Fired Brick Machine represents the perfect fusion of German precision and Chinese innovation.

With continuous technological progress and global service support, QGM remains committed to promoting smart, energy-saving, and eco-friendly solutions for the concrete industry — empowering global customers to build a greener and more sustainable future.