Ushering in a New Era of Green Building Materials QGM Smart Non-Burning Block Machine Redefines the Industry

As China's dual-carbon goals (carbon peak and carbon neutrality) advance, energy-efficient buildings and green materials have become the core drivers of industry development. As a leading domestic manufacturer of eco-friendly equipment, QGM has launched a new generation of smart non-burning block machines, focusing on high efficiency, energy savings, environmental protection, and intelligent connectivity. This solution empowers clients to achieve resource recycling and smart production upgrades.

1. Product Overview

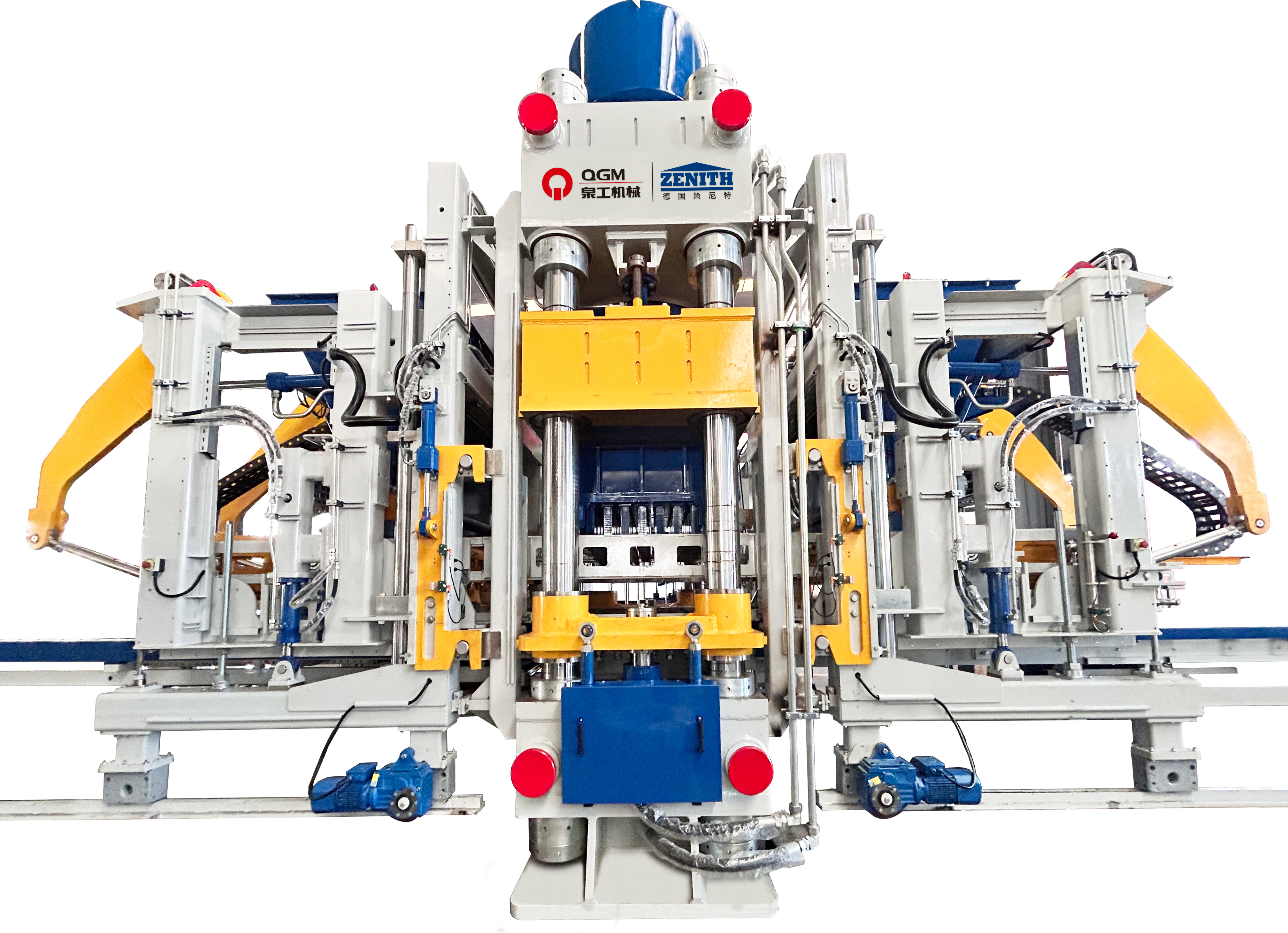

Model: QGM ZN1500Y Smart Non-Burning Block Machine

Core Functions:

Uses solid waste, industrial tailings, and other raw materials;

No need for high-temperature kilns — blocks are formed directly via high-pressure static compaction, minimizing energy consumption and carbon emissions.

Smart Control:PLC + Touchscreen + Cloud Platform integration, enabling real-time monitoring of mixing, pressure, vibration, temperature, and other key parameters;

One-touch recipe switching for versatile production.

Green & Low-Carbon:Compared to traditional fired brick machines, every 10,000 bricks produced with the ZN1500I reduces CO₂ emissions by approximately 35 tons, supporting low-carbon manufacturing.

2. Key Technology Highlights

Multi-Process Compatible Mixing System

Supports precise blending of cement, fly ash, slag, tailings, and construction waste;

Capable of producing a wide range of products including antique-style bricks, landscape bricks, curbstones, and solid blocks;

Features automatic weighing and online detection with ±0.5% accuracy, ensuring consistent product strength and appearance.

High-Pressure Static Compaction Technology

Maximum static pressure up to 1,500 tons, paired with high-strength steel molds for superior density and compressive strength;

Rotary multi-station design enables continuous production, reducing cycle time.

Intelligent Vibration & Compaction System

Servo vibrators combined with electro-hydraulic proportional control, automatically adjusting amplitude and frequency based on brick type;

Adapts to various densities and colors across different production lines, ensuring smooth surfaces and fine textures.

Cloud-Based Data & Remote Operations

Real-time equipment data uploads to the QGM Cloud Platform, supporting trend analysis, fault diagnostics, and maintenance reminders;

Remote experts can fine-tune parameters or push optimization recommendations, reducing on-site maintenance costs.

3. Typical Application Cases

Construction Waste Recycling Plant in Hunan

Client uses QGM ZN1500Y Smart Non-Burning Block Machine to produce premium landscaping bricks from fly ash and construction waste;

Three months post-commissioning: stable equipment operation, 99% product yield, and 20% annual output increase.

Urban Renewal Project in Southwest China

The project integrates QGM block machines with smart non-burning machines, utilizing locally sourced materials to reduce logistics costs;

Upon project completion, all curbstones and plaza bricks were produced as non-burning blocks, significantly reducing energy consumption and noise pollution, and earning praise from local governments and environmental agencies.