ZN2000-2 High-Capacity Performance for Demanding Block Production

As concrete product manufacturing moves toward larger scale, higher standards, and tighter delivery schedules, equipment reliability becomes a strategic asset rather than a technical option. The ZN2000-2 block making machine is engineered for manufacturers operating high-output plants where stability, consistency, and long-term performance are essential.

Designed for large-format and high-volume production, the ZN2000-2 supports a wide range of concrete products, including hollow blocks, solid blocks, paving stones, curbstones, and other infrastructure-related elements. Its generous forming area and robust compaction system enable efficient production of both standard and large-size products, meeting the needs of municipal, industrial, and commercial construction projects.

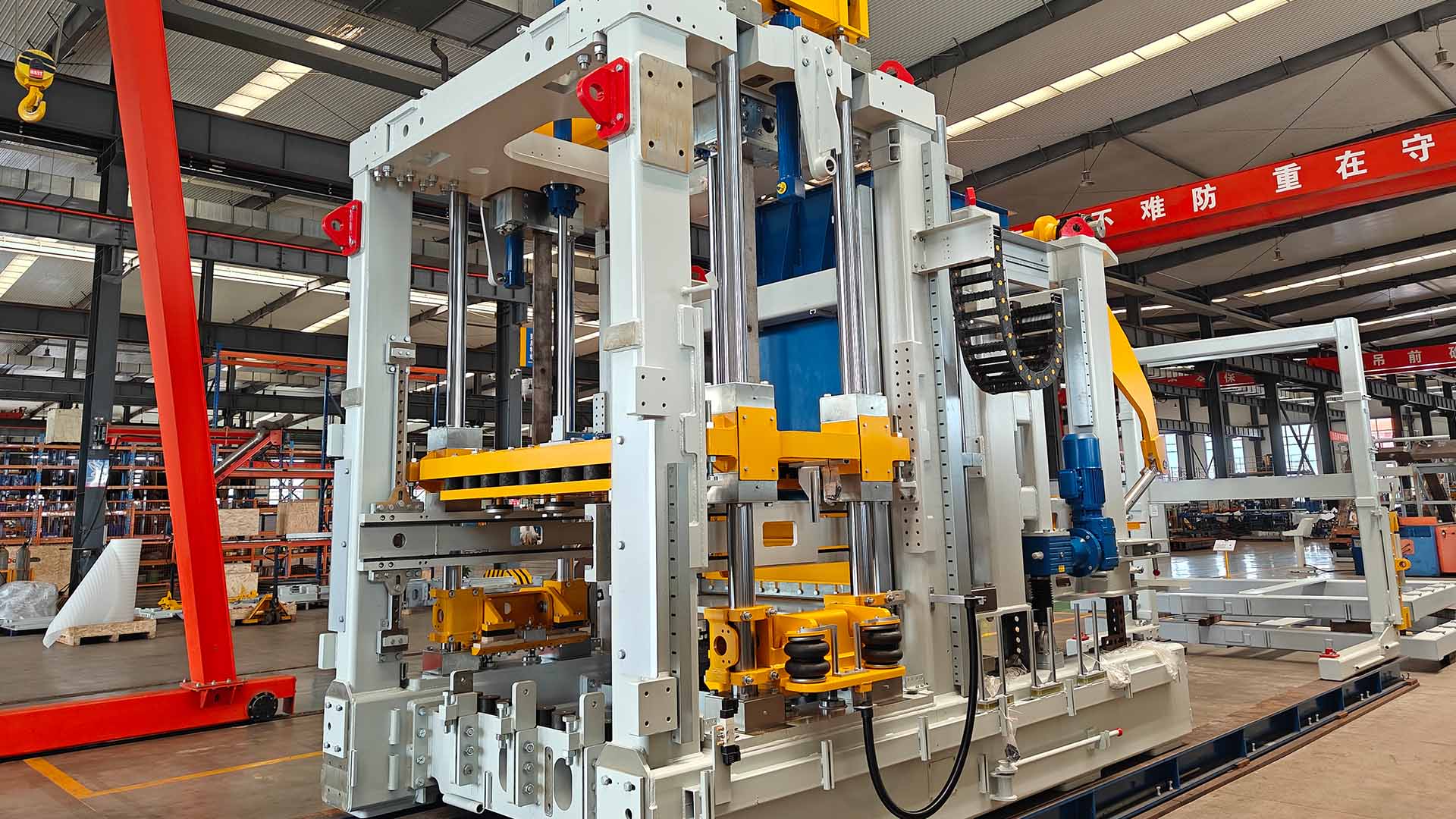

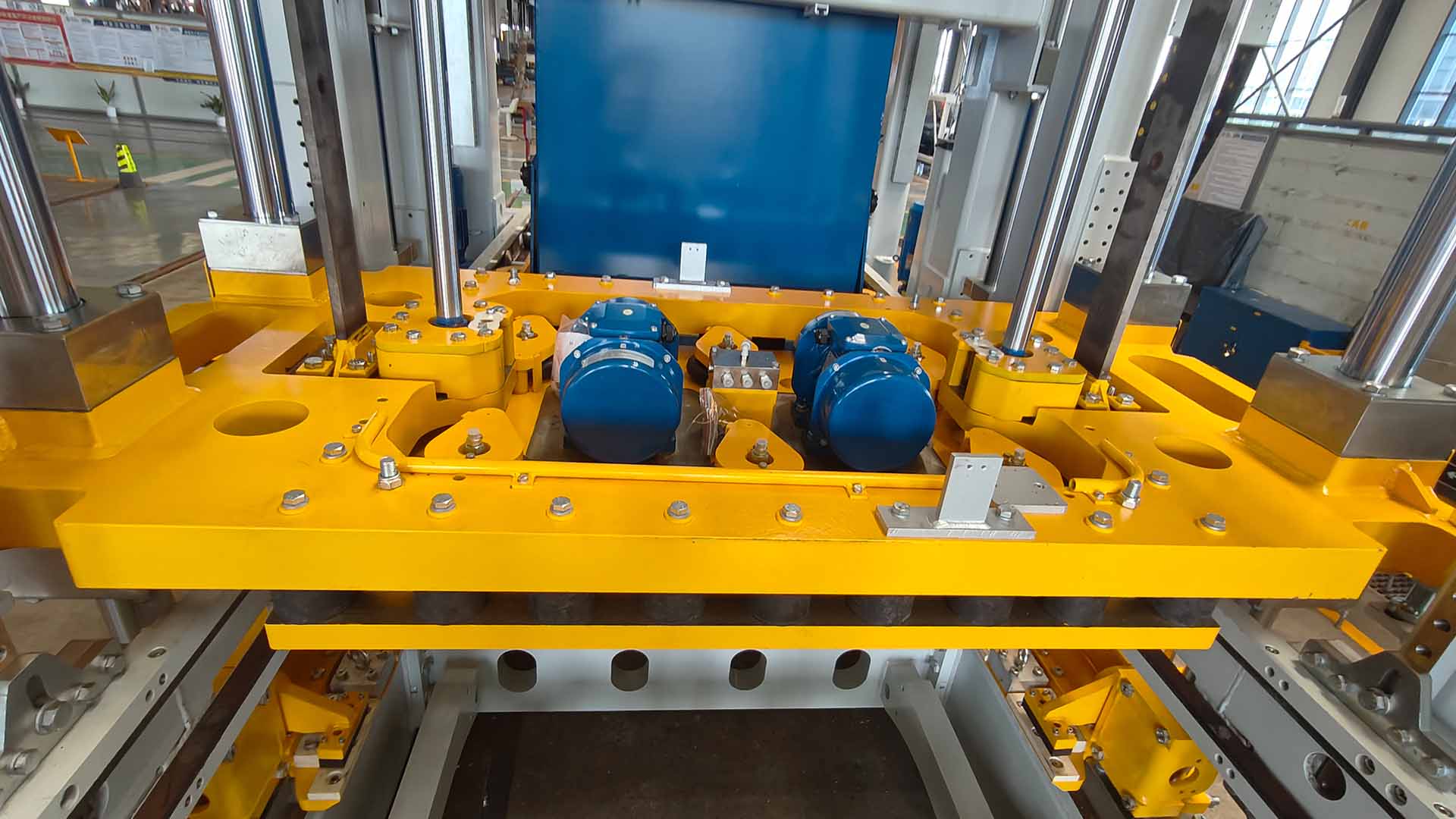

At the core of the ZN2000-2 is a powerful forming system that combines controlled vibration with optimized compaction force distribution. This ensures uniform density throughout the entire mold surface, even under high production loads. As a result, finished products achieve excellent strength, dimensional accuracy, and surface quality, maintaining consistency across long production runs.

The machine’s mechanical structure is designed for heavy-duty operation. A reinforced frame and high-strength components provide exceptional rigidity, reducing deformation and vibration loss during continuous operation. This structural stability plays a critical role in maintaining precision, minimizing wear, and extending service life in multi-shift, high-capacity environments.

Operational stability is further enhanced by an advanced control system that allows precise management of production parameters. Clear process visualization and reliable automation reduce operator dependency and support consistent cycle times. Even when producing different block types or switching molds, the ZN2000-2 maintains predictable and stable operation.

The ZN2000-2 integrates seamlessly into fully automated production lines. It works efficiently with pallet handling systems, high-capacity stacking units, curing chambers, and downstream processing equipment. This smooth integration ensures balanced material flow across the entire plant, reducing bottlenecks and maximizing overall line efficiency.

From an economic perspective, the ZN2000-2 is designed to optimize total production cost at scale. Efficient energy utilization, reduced material waste, and minimized downtime contribute to improved productivity and lower cost per unit. For manufacturers supplying large infrastructure projects or operating centralized production bases, this translates into strong and sustainable returns on investment.

Beyond immediate output, the ZN2000-2 is built as a long-term production platform. Its modular design allows for future automation upgrades and capacity expansion, enabling manufacturers to adapt to evolving market demands without disrupting existing operations.

ZN2000-2 is more than a high-capacity block machine. It is a solution for manufacturers who require industrial-level reliability, consistent quality, and scalable production capability.

ZN2000-2

Built to carry heavy production—today and into the future.