Delivery Update | QGM ZN900-2C Intelligent Non-Burning Block Machine Empowers Green Building Production

At QGM’s production base in Quanzhou, a newly assembled ZN900-2C Intelligent Non-Burning Block Machine has completed its final inspection and is ready for delivery to a green building materials project. This equipment will support local efforts in solid waste recycling and energy-efficient manufacturing, demonstrating QGM’s commitment to sustainable production.

1. High Efficiency & Stable Performance

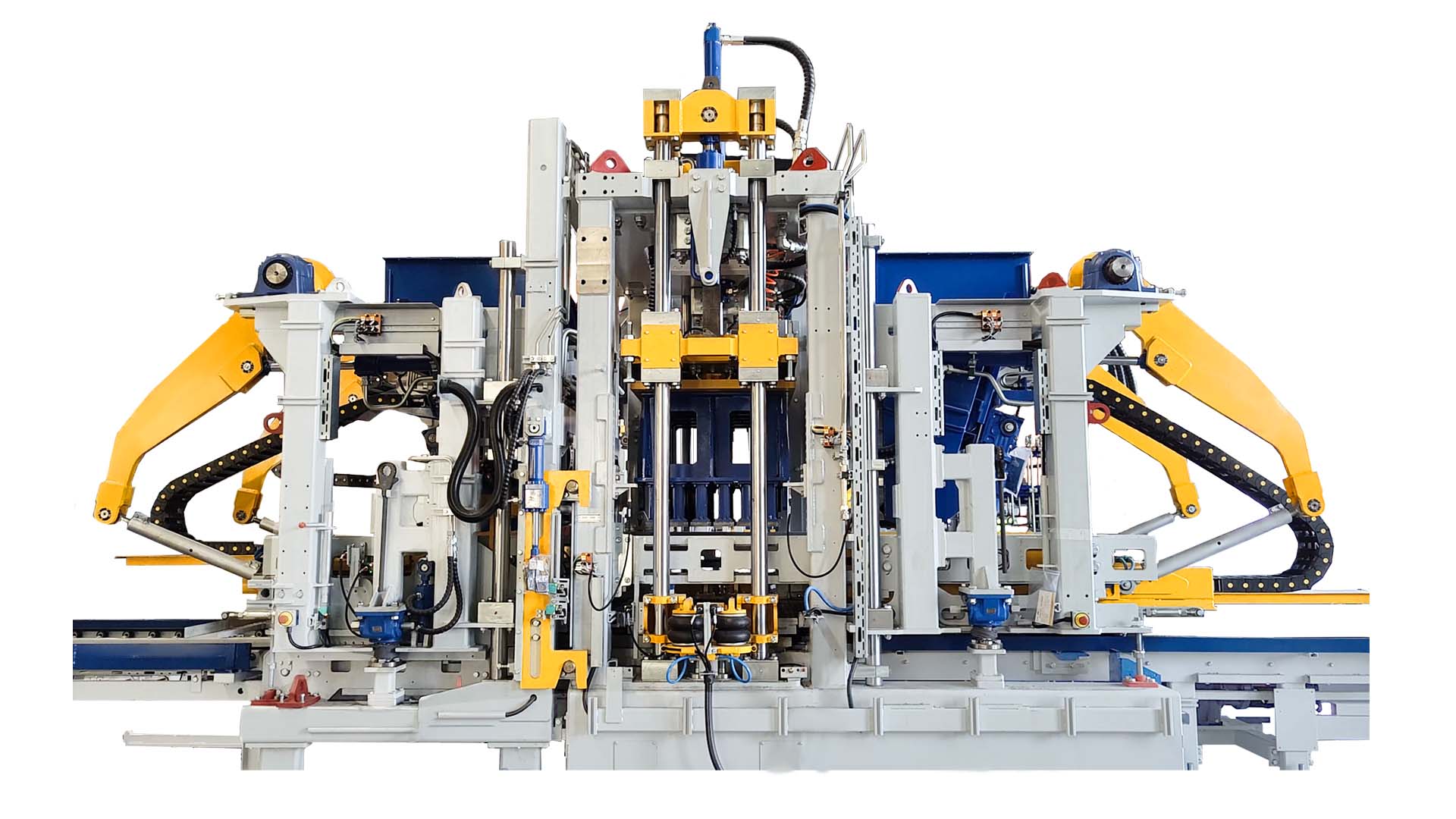

The ZN900-2C is one of QGM’s flagship mid-size models, integrating feeding, distribution, vibration, pressing, demolding, and stacking into a fully automated cycle. Its short forming time and high density output make it suitable for a wide range of products — from solid and hollow blocks to paving stones, curbstones, and permeable bricks.

The machine adopts a servo vibration system combined with a hydraulic press-vibration integration design, allowing precise frequency adjustment between 20 and 60 Hz. This delivers uniform compaction and superior strength. Its modular structure simplifies maintenance and upgrades, ensuring flexibility for various production needs.

2. Smart Control for Consistent Quality

Equipped with a Siemens PLC control system and a user-friendly touch interface, the ZN900-2C monitors key production parameters in real time. It automatically adjusts vibration frequency, distribution speed, and hydraulic pressure to ensure consistent product quality.

Through the QGM Industrial Cloud Platform, production data can be remotely collected and analyzed. Plant operators can monitor machine status from mobile devices, perform remote diagnostics, and schedule maintenance in advance — a significant step toward digital and smart factory management.

3. Energy Saving & Environmentally Friendly

As a non-burning block machine, the ZN900-2C uses cold pressing technology, eliminating the need for high-temperature kilns and reducing CO₂ emissions. It can effectively utilize construction waste, fly ash, tailings, and slag as raw materials, turning industrial waste into valuable building products. This not only lowers production costs but also supports China’s “Dual Carbon” goals for energy saving and emission reduction.

4. Strict Quality Control & Reliable Delivery

Before shipment, QGM’s technical engineers conducted a comprehensive inspection of the ZN900-2C, including hydraulic sealing tests, vibration stability tests, and electrical logic verification. Only after passing these strict quality standards is the machine cleared for delivery.

During packaging, each unit is secured with anti-vibration supports and protective materials to prevent moisture or impact damage in transit, ensuring the machine arrives in perfect working condition.

5. Comprehensive After-Sales Service

At QGM, delivery marks the beginning of service — not the end. A dedicated installation and technical team will provide on-site setup, commissioning, and operator training to help customers achieve rapid production startup.

Follow-up visits and periodic inspections ensure long-term machine reliability, while the company’s service network and spare-parts support minimize downtime and maintenance costs.

🌱 QGM Group remains committed to advancing smart manufacturing and green construction. The ZN900-2C embodies this mission — delivering efficiency, reliability, and sustainability for modern block production. Looking ahead, QGM will continue to empower global clients with high-performance, eco-friendly solutions that drive the industry toward a greener and more intelligent future.