The “Last Mile” of Production Lines How Stacking Systems Improve the Efficiency of Block Production

In modern non-fired block production lines, the block making machine determines product quality, while the stacking system directly affects production rhythm, labor cost, and on-site management efficiency. As a critical auxiliary unit in the production process, stacking machines are responsible for pallet handling, stacking, and buffering, playing an essential role in achieving automated and continuous production.

To meet different production scales and plant conditions, QGM has developed a comprehensive range of stacking solutions, which can be flexibly integrated with various block making machines and automated production lines.

Single-Pallet Stacker: Compact Structure, Stable Operation

The single-pallet stacking machine is designed for small to medium automated production lines. Featuring a compact structure, stable performance, and easy maintenance, the machine accurately aligns and stacks individual pallets after demolding, ensuring orderly pallet storage for curing or transportation.

With a small footprint, this solution is ideal for factories with limited space or those at an early stage of automation, reducing manual intervention while maintaining production continuity.

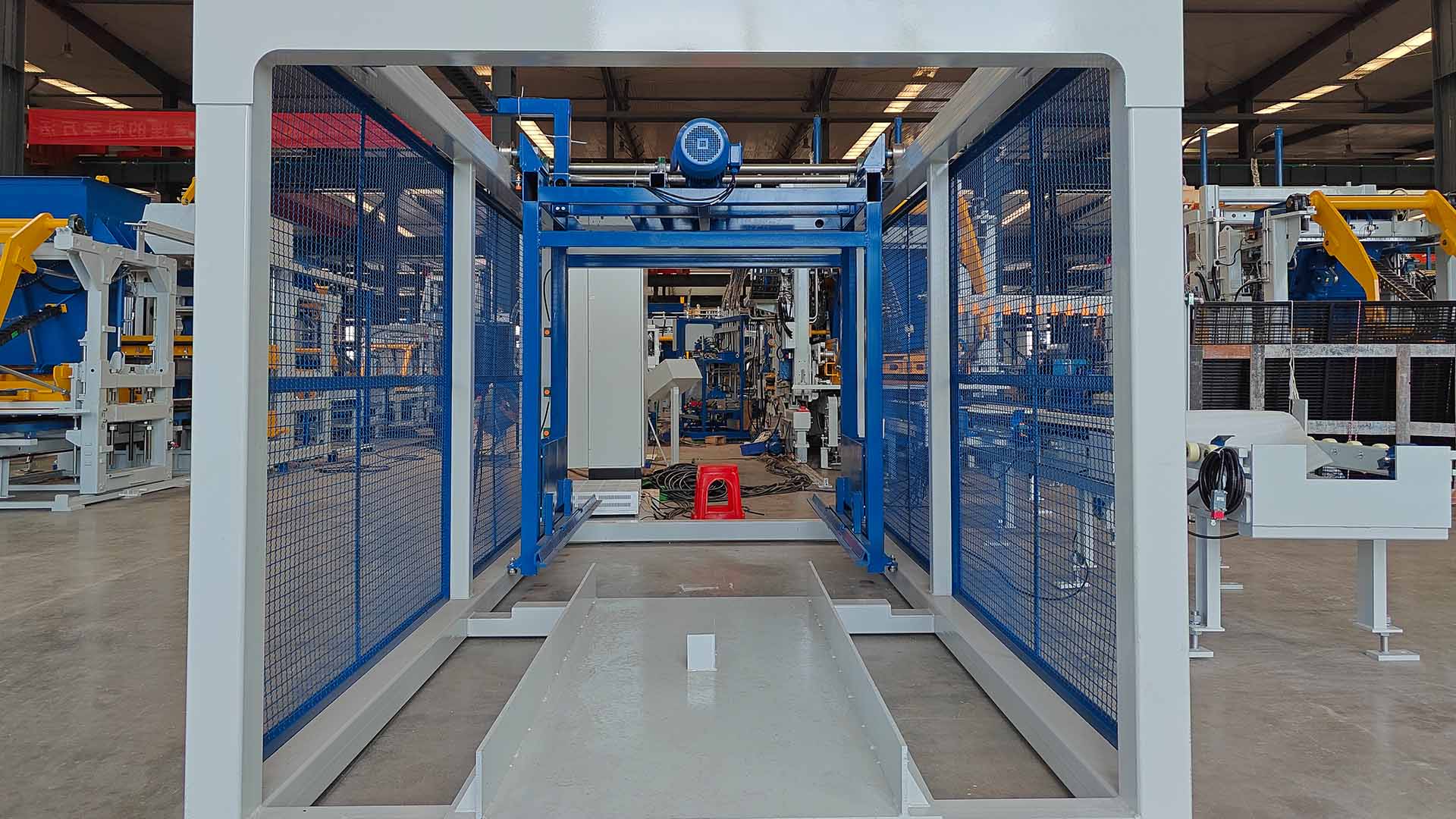

Double Stacker: Higher Throughput for High-Efficiency Lines

For production lines with higher cycle speed requirements, the double stacking machine uses a dual-station or dual-channel configuration to enable alternating stacking and buffering of pallets. This design minimizes waiting time and prevents pallet circulation delays from affecting the main machine’s operation.

This solution is widely applied in medium- to large-scale non-fired block production lines, ensuring smooth coordination between the block making machine, curing system, and downstream processes.

Diverse Lifting Solutions for Different Operating Scenarios

To accommodate various plant layouts and operational requirements, QGM offers multiple pallet lifting and handling solutions within the stacking system, including:

Simple rack-type pallet lifter, with a straightforward structure and cost-effective design

Forklift-arm pallet lifter, using forklift handling for high flexibility and easy line adjustments

Pallet elevator, providing precise height adjustment to connect seamlessly with conveyors and curing areas

Pallet lowering and buffer system, serving as a buffer unit in high-cycle production lines to balance upstream and downstream processes and eliminate bottlenecks

These solutions can be freely combined according to factory layout and production rhythm, enhancing overall system flexibility.

System-Oriented Design for Long-Term Operation

Although stacking machines do not participate directly in block forming, they have a significant impact on production efficiency and site organization. QGM designs stacking systems with full consideration of pallet standardization, mechanical stability, and maintenance convenience, ensuring reliable performance under long-term, high-load operation.

Through coordinated integration with block making machines, conveying systems, and curing equipment, stacking machines become an essential component of a complete automated production solution, rather than isolated auxiliary equipment.

Conclusion

From single-pallet stackers to double stacking systems, from basic lifting devices to intelligent buffering solutions, the configuration of stacking machines plays a decisive role in the efficiency and manageability of non-fired block production lines. QGM will continue to refine its auxiliary equipment portfolio, delivering stable, efficient, and easy-to-manage intelligent production solutions for concrete product manufacturers worldwide.