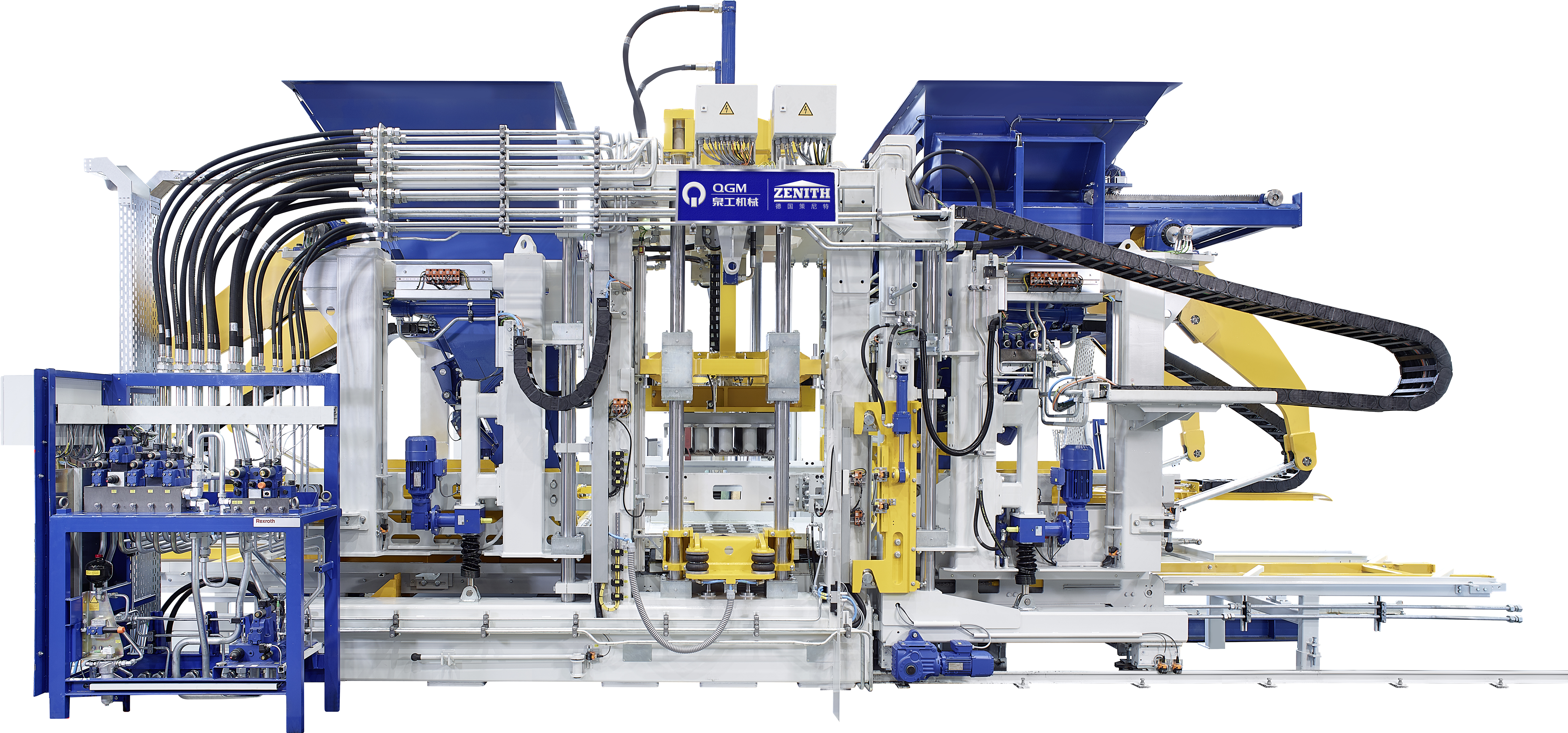

Automatic Fly Ash Brick Making Machine

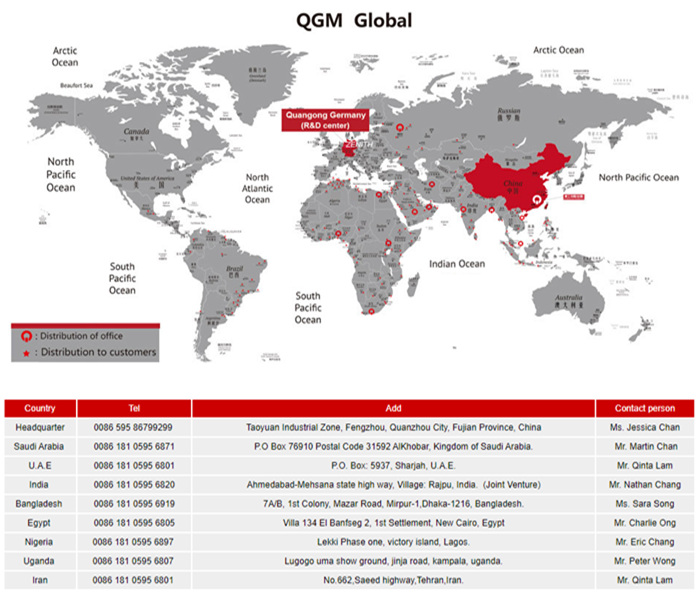

- QGM ZENITH

- Design By German & Made-in China

- 30-60 days

Brand Model NO.:ZN1500C

ZN1500C is a model of European standard brick machine, which means totally strict accordance with German production technology and craftsmanship and manufactured in China. It integrates various functions and can produce standard concrete products such as paver, curbstone and solid brick on a large scale.

ZN1500-2 brick machine adopts German technology, the leading technology for block machine in the world. German technology is known for its rigor and simplicity, paying more attention to the overall performance, efficiency, and machine quality.

ZN1500C Fly Ash Brick Making Machine are produced in China, strictly accordingly to German technology and craftsmanship. Compared with other brand of block machines,

ZN1500C concrete brick making machine have more stable performance, higher production efficiency and lower failure rate. In terms of performance, efficiency, energy-saving, environmental protection, etc., it is far ahead of other block machines in the market.

Technical Parameters

| Specification | ZN1500C | ZN1800C |

| Maximum forming area | 1300×1050mm | 1300×1300mm |

| Block height | 50-500mm | 50-500mm |

| Cycle time | 20~25s (Depending on block type) | 20~25s (Depending on block type) |

| Vibration force | 160KN | 200KN |

| Pallet size | 1,350×1,100\1,200×(14-50) mm | 1,400×1,400mm |

| Production per mould | 390×190×190mm(15pcs/mould) | 390×190×190mm(18pcs/mould) |

| Bottom vibration | 4×7.5KW(SIEMENS) | 4×7.5KW(SIEMENS) |

| Tamper head vibration | 2×1.1KW | 2×1.1KW |

| Control system | SIEMENS | SIEMENS |

| Total power | 111.3KW | About 120KW |

| Total weight | 18.3T(without facemix device) | 19.5T(without facemix device) |

| 25.2T(with facemix device) | 27.5T(with facemix device) | |

| Machine size | 10,920×3,250×4,485mm | 11,600×3,250×4,500 mm |

QGM ZN1500C Automatic Block Making Machine with Five Core advantages:

1.Frequency conversional technology & control

Reduce the motor starting current and soft start function control, prolong the life of the motor. Main vibration adopt low frequency standby, high frequency operation, improve the speed of operation and product quality. Reduce mechanical accessory and motor damage, prolong the life of the motor and mechanical.The frequency conveter saving about 20%-40% power than the traditional conveter. Frequency braking system timely consumption excessive power generated during the operation , make the motor stop smoothly.

2.Germany Siemens PLC control system, Siemens touchscreen, Germany

Easy operation,low failure ratio, machine running stability and high reliability.Use the most-advanced industrial internet technology, realize remote trouble-shooting & maintenance. PLC and touchscreen use the PROFINET internet together, convenient for system diagnosis and WEB expansion. Achieve problem diagnosis and alarm system constantly, convenient for machine maintenance and troubleshooting. PLC running data for permanent preservation.

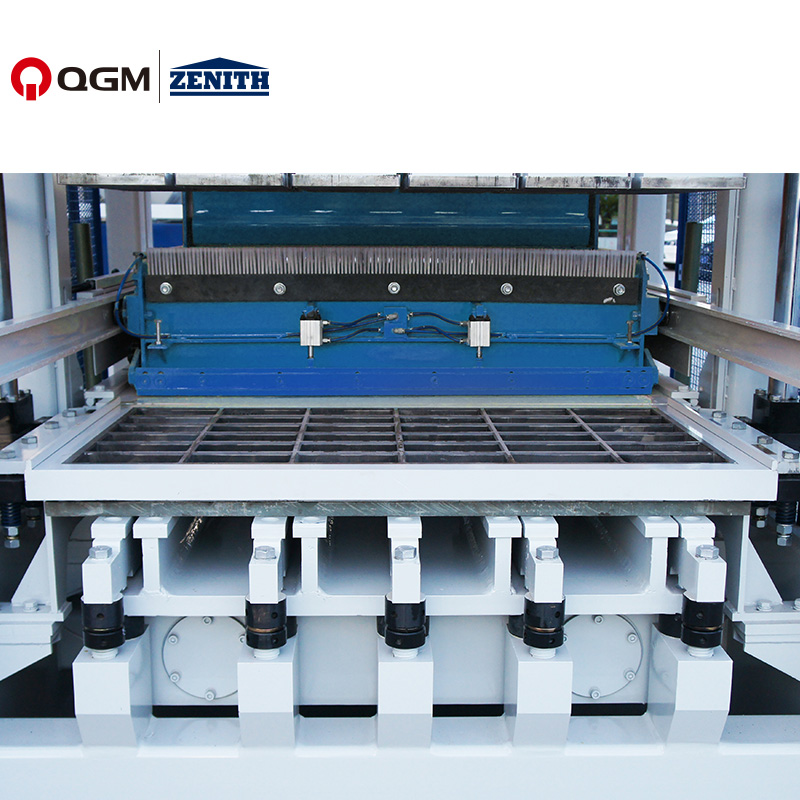

3.Vibration System

Vibration table consists with dynamic table and static table. When vibration begin,dynamic table vibrate,static table remain static.The structure is designed to ensure the amplitude of the vibration table, so as to ensure the high quality of concrete products. Vibration table using HARDOX steel. Vibration mode: using the vibration table vibration + top mould vibration; vibration motor installation vibration damping device and air cooling device.

4.Feeding System

Motor use SEW motors, which control two mixing shafts. Feeding frame, bottom plate and mixing blade are made of high-duty HARDOX steel, the location of bottom plate can be adjusted.Feeding system have sealing device to prevent leakage. The door of the discharging gate is controlled by the SEW motor.

5.Hydraulic Station

Hydraulic pumps and hydraulic valves adopt international brands. Tube uses “Flange Connection” , convenient installation and maintenance. Multi-point pressure detection point, convenient detection. Digital temperature and blockage alarm function. Motor and pump connection, flange connection, good coaxial. Dynamic proportional valve and constant power pump, speed regulation, voltage regulation, energy saving.